Category column

- 0755-88869982-604

- dx@szsurpass.com.cn

- 5th Floor, Building D, No. 96, Fenghuang Lingxia Road, Fuyong Street, Bao'an District, Shenzhen

- Content

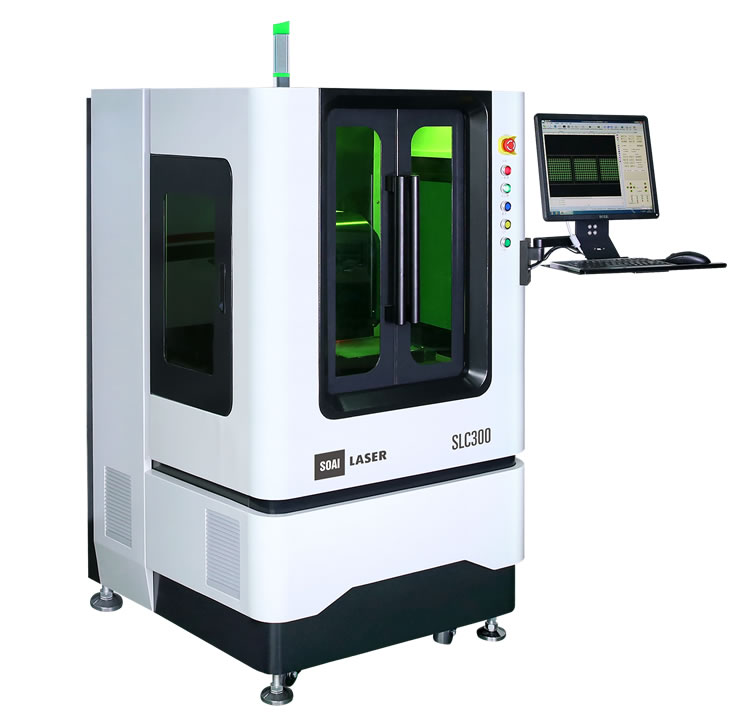

One. Product introduction:

Ultraviolet laser cutting machine belongs to the series of laser cutting machines. It is developed by using a 355nm ultraviolet laser. This machine adopts a third-order intracavity frequency doubling technology. Compared with infrared lasers, the 355 ultraviolet light has a very small focus spot and can be used in a large scale. It can reduce the mechanical deformation of the material to a certain extent and the processing heat effect is small, because it is mainly used for ultra-fine cutting and engraving, and is especially suitable for marking, micro-holes, glass materials and high-speed division of glass materials and wafer Carry out complex graphics cutting and other application areas.

High-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials, so that the molecules are separated from the object. This method does not generate high heat. The ultraviolet laser has a very small focus spot and almost no thermal effect on the processing, so it is called cold processing. Therefore, it is suitable for ultra-fine marking, engraving and cutting of special materials.

two. Features

1. Economical configuration, excellent performance, reliable quality, and high cost performance. This equipment uses high-quality high-power violet lasers. The laser power density is uniform, the light spot is fine, and the output light power is stable, which meets the needs of mainstream market applications.

2. This equipment adopts an imported brand of digital high-speed scanning galvanometer, which is small in size, fast in speed, excellent in stability, and its performance has reached the international advanced level.

3. Modular design, flexible application.

This equipment provides a precise interactive workbench, and is equipped with an automatic/manual working mode to meet the needs of customer's multi-station production automation and improve equipment production efficiency.

4. A wide range of applicable materials to make up for the lack of infrared laser processing capabilities;

5. The beam quality is good, the focused spot is small, and ultra-fine marking can be realized;

6. The heat-affected zone is small to avoid being damaged by the processed materials, and the yield is high;

7. Fast cutting speed, high efficiency and high precision;

8. No need for consumables, low cost of use and maintenance;

9. The performance of the whole machine is stable and can run for a long time;

Using UV ultraviolet laser as tool, cold processing method, compact structure, easy installation, simple operation and convenient maintenance. Almost all materials can be processed, with powerful functions, precise control and high processing efficiency. It is a good helper for the development of innovative products.

1. Faster production

Quickly divide the PCB produced by the jigsaw into independent circuit boards, process LTCC, process prepregs, drill holes in FR4, drill micro-holes, and laser directly form circuit patterns, etc. Compared with other processing methods or other lasers, the ultraviolet laser has more neat cutting edges and higher outline dimension accuracy. The product processing mode can be switched without gaps, just click the software menu to import a new processing item.

2. Higher performance

SLC300 is easy to install, adopts air-cooled UV laser, connects to a vacuum cleaner, inserts compressed air, and plugs in the power supply to work. The equipment has a compact design and structure. It adopts a cross sliding table combined with CCD visual motion control to achieve high-speed motion and automatically capture and position products, with higher efficiency and higher accuracy. Automatic focusing means that the workpiece is always in the laser focus range. The integrated vacuum adsorption platform, including soft materials, flexible materials, and thin substrates, can be smoothly fixed.

3. More flexible

SLC300 can process ceramics, LTCC (green porcelain), FR4, Rogers materials, cover films, metal foils, flexible or rigid-flexible materials and other materials accurately, cleanly and quickly.

4. Easy to operate

Simple operation is the purpose of all laser equipment design. The powerful software function can easily convert common design data into laser processing data. The laser parameters are processed and edited according to different materials, and the memory is saved. In addition, the software can set different user levels, and users can set corresponding permissions for the device according to different levels.

5. Safer use

The safety level of the SLC300 laser system is Class I, and the design adopts two laser safety protections to effectively isolate the laser radiation. No special protective measures are required during laser processing.

three. Performance parameter

Project name

Technical parameters

Maximum laser average power

The maximum average laser power

5W

Laser wavelength

The laser wavelength

355nm

Standard engraving range

Standard engraving range

110*110

Engraving line speed

Engraving speed

5000mm/s

Repeatability

Repeat accuracy

±0.02mm

electricity demand

Power demand

220V±22V / 50Hz / 10A

Power consumption of the whole machine

Consumed power

800W

Operating temperature

Working temperature

20-32℃

Relative humidity

Relative humidity

<80%

·Laser parameters

Type

Name

Parameters

Information

Laser system

Laser

Laser

UV-5

Synrad

Beam expander

Beam expander

5X

RONAR-SMITH

Galvanometer

Galvanometer

10mm

Customized

Focus lens

Focus lens

110*110

RONAR-SMITH

Control system

Marking control card

Marking control card

USC-1

SCAPS

Marking software

Marking software

SAMLIGHT

SCAPS

CCD camera

CCD camera

USB

Customized

Height sensor

Height sensor

OMRON

Control power

Control power supply

Customized

Name

Parameter Description

Product number

SLC300

Laser output power

>10W

Laser wavelength

355nm

Beam quality

M2 ≤1.4

Laser type

continuous

work plan

(110x110) MM can be equipped with other stroke slides

CNC system

Support 3-axis linkage

Cutting speed

0-7000mm/m (depending on material and melting depth requirements)

Minimum spot diameter

0.015MM

Whole machine energy consumption

≤1.5KW

electricity demand

Three-phase AC AC220V/50Hz

Safety protection level

IP54

Laser safety level

Type 4

four. Scope of application

·Laser direct writing circuit

·Cutting rigid and flexible materials

·Forming TCO/ITO

·LTCC cutting and drilling

·Laser direct writing circuit forming

- Application of laser cutting machine in light industry 2021-02-04

- Application of laser cutting machine in sheet metal industry 2021-02-04

- The green working technology of the laser cutting machine is more advanced 2021-02-04

- The laser cutting machine should pay attention to when cutting different materials 2021-02-04